Distillery plant fabrication involves the design, manufacturing, and installation of specialized equipment for processes like raw material pre-treatment, fermentation, distillation, and byproduct management, to produce alcohol and other high-value products from feedstocks such as molasses or grains

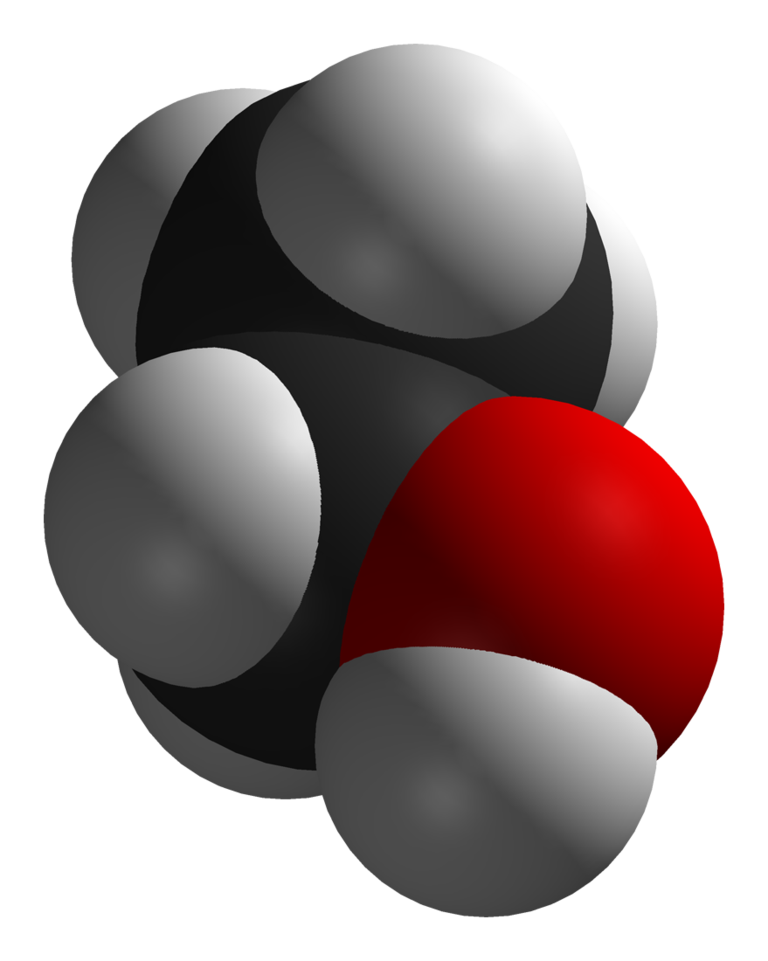

Ethanol or ethyl alcohol has three primary markets: alcoholic beverages, industrial applications and fuel additive. it’s can be produced from a wide variety of feedstocks rich in simple sugars or starches. The industry is dominated by corn, but other include sugarcane, sugar beets, grain sorghum (milo), wheat, and barley.

Depending on the raw materials and the degree of chemical purity, rectified alcohol has different varieties, for example: First Grade (for the production of alcoholic beverages is not used), Highest Grade, Base, Extra, Lux, Alpha.

Dependence on the type of raw materials and the technological scheme of production, the product yield is 81.5–93 % of the theoretical recovery.

Table 1. Production Steps in Corn Dry-Milling (exemple)

| Production Steps | Primary Inputs | Primary Outputs | Operations Performed |

|---|---|---|---|

| Receipt, storage and inspection | Shelled corn | Stored corn | – Receive shelled corn by truck or rail – Unload corn into receiving pits – Transfer corn to storage bins or silos – Inspect corn upon receipt |

| Cleaning | Shelled corn from storage | Cleaned whole corn kernels | – Pass corn through screeners or scalpers to remove oversized and smaller material – Pass corn through other steps (e.g., destoner, magnet) to remove other unwanted objects |

| Milling | Cleaned whole corn kernels | Fine corn flour | – Transfer whole kernels to a hammer mill, impact mill, or other milling operation – Crush and grind shelled corn into a fine flour |

| Liquefaction | Fine corn flour | “Mash” (liquid mixture of corn flour and other corn parts) | – Mix fine corn flour with water in large cook or slurry tanks – Add chemicals to adjust the slurry’s pH – Add enzymes (alpha amylase) to solution to break down corn starch into dextrins |

| Saccharification | “Mash” | Mash with starch broken down into simple sugars | – Add enzymes (glucoamylase) to mash to breakdown dextrins into glucose |

| Fermentation | Mash with starch broken down into simple sugars | “Beer” mixture containing ethanol and solids from grain and yeast; and carbon dioxide | – Add yeast to convert glucose in mash into ethanol and carbon dioxide – Pump beer to separate storage vessel |

| Distillation and dehydration | “Beer” mixture | ENA / Denatured ethanol | – Pump beer mixture into a continuous distillation system, which may contain multiple columns – Collect purified ethanol from the vapor portion of columns and spent solids (stillage) from the bottom – Purify ethanol stream in rectifying column, molecular sieve, or other production equipment – Add denaturant to ethanol in cases where ethanol is not used for human consumption – Store denatured ethanol in tanks until distribution |

| Co-product processing | Stillage from distillation columns | Wet distillers’ grain and/or dried distillers’ grain with solubles (DDGS) | – Reduce moisture content in stillage by using centrifuges, dryers, or other equipment – Make selected co-products by mixing varying quantities of dry products with other materials – Load dry products into trucks, railcars, or other means of transport for distribution |

Our engineers is available to you by phone or e-mail. Get in touch.

+380 (97) 5781 934 (WhatsApp)